Our Products

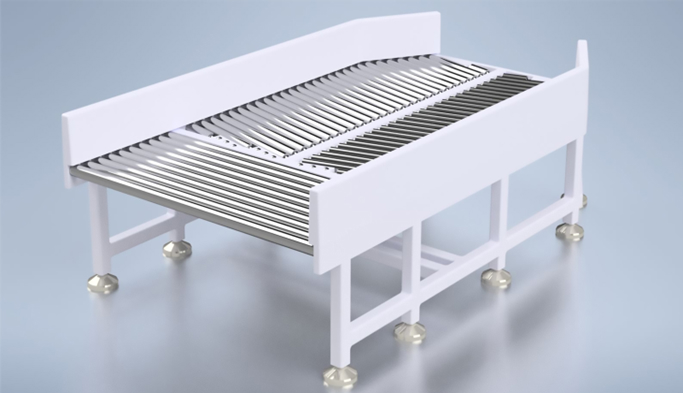

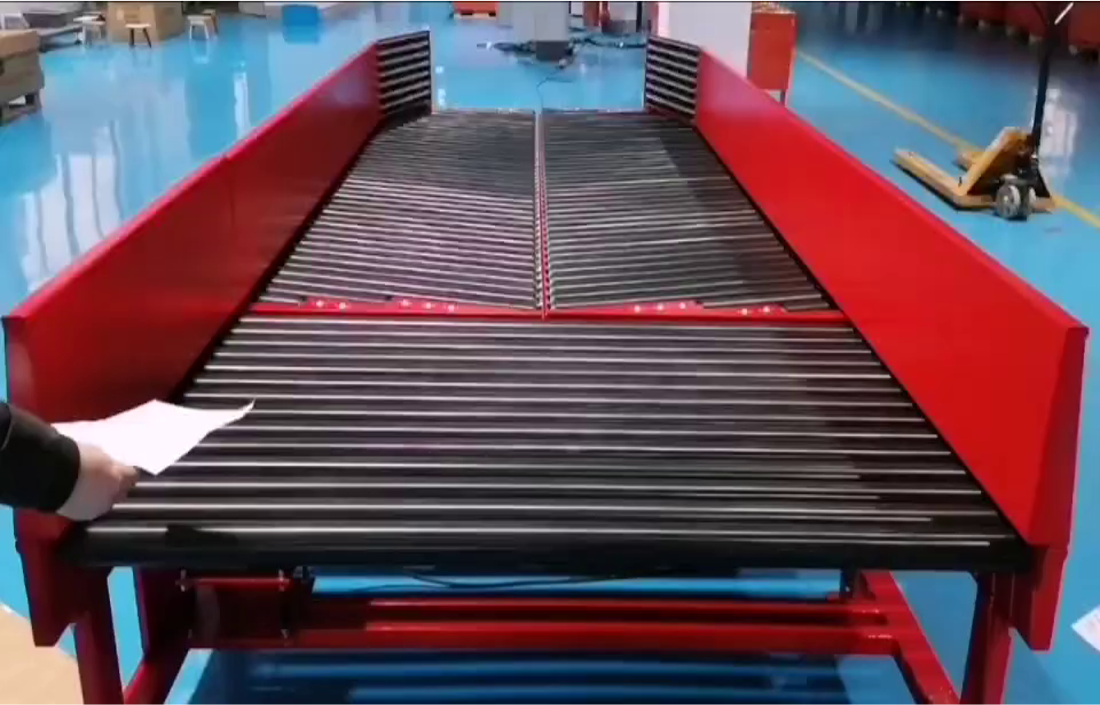

Telescopic Belt Conveyor

Telescopic belt conveyor can be used to load/unload any type of loose-loaded cargo - typically parcels, boxes, sacks & tyres. An intuitive smart-pad on either side enables precise control of the boom's elevation and telescopic movement. Push buttons at the operator end of the boom control activation, lights, belt direction etc. Our company’s annual output more than 3000PCS.

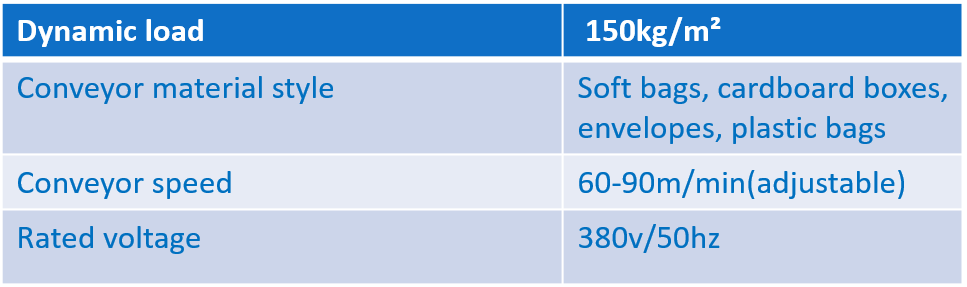

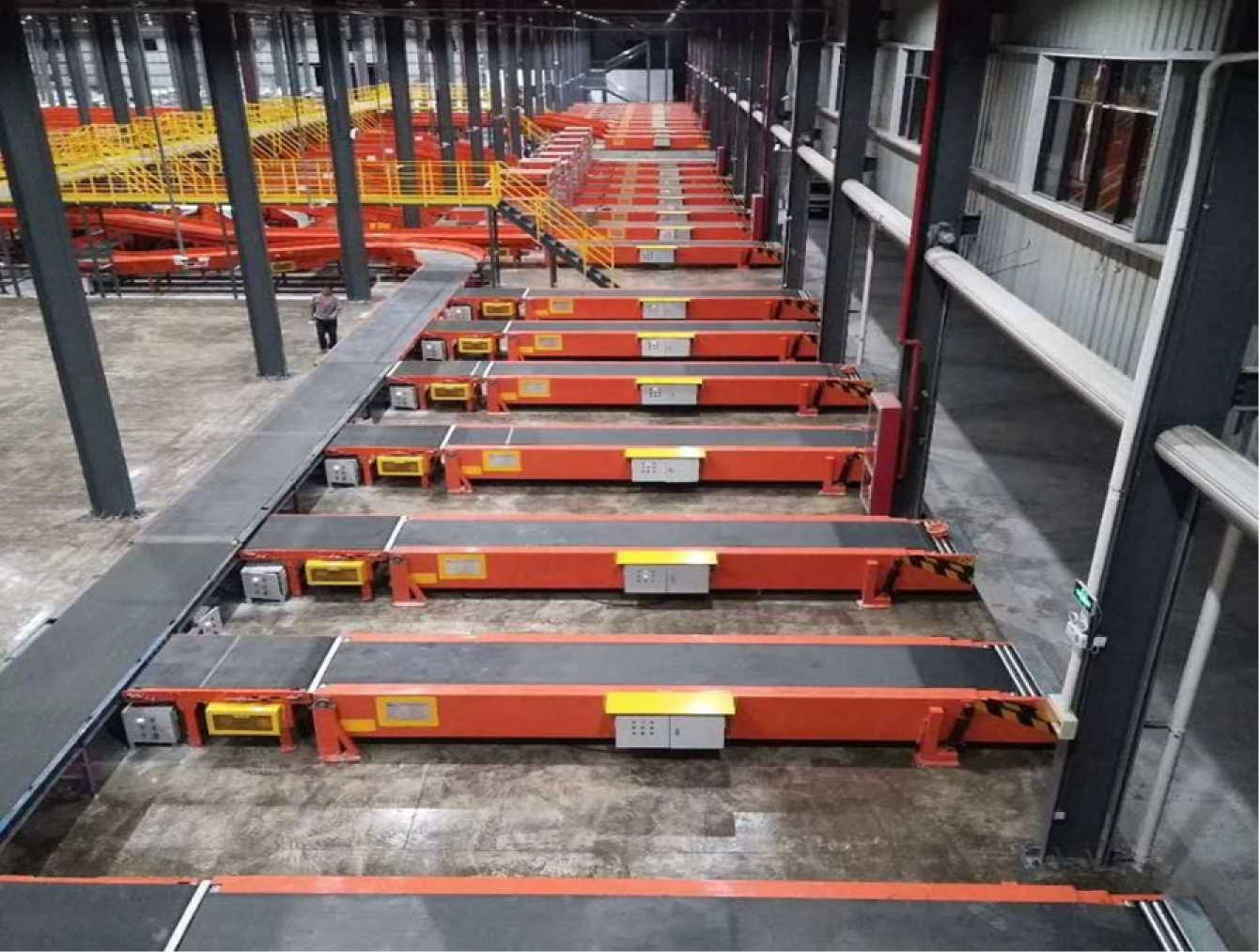

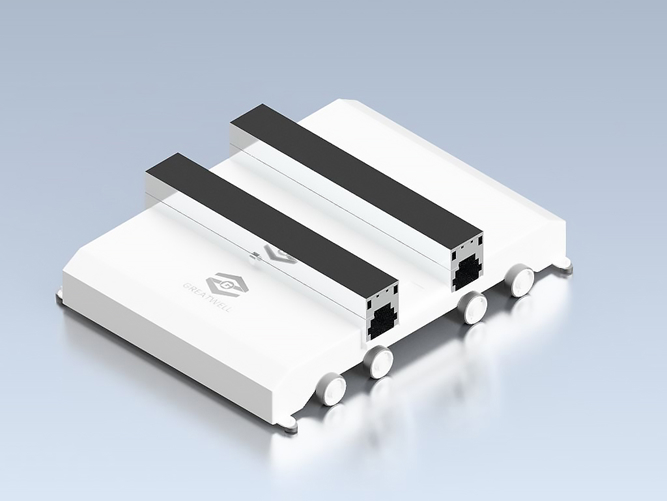

Module belt sorting system

The Module belt sorting system can achieve flexible sorting, wide range of sorting objects, and Module can be customized customization, easy easy assembly, strong exchanges, and durability . Energy saving and environmental protection. Can effectively reduce the cost of manual operation and improve sorting efficiency. Implement flexibility, unmanned Intelligent sorting operations. Applicable environment: logistics express transit warehouses, branch offices, receiving and shipping areas of warehouses, as well as the range of precise sorting required.

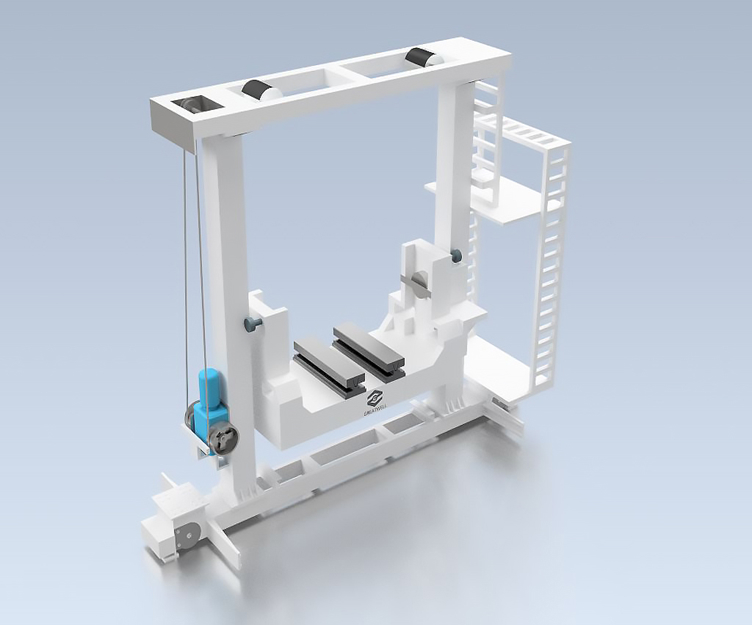

Whole Vehicle loading and unloading

Automatic Vehicle Loading and Unloading System (ATLS) is a material handling system that utilizes different types of conveyors, pulleys, or forks to achieve automatic loading and unloading of entire truck or trailer cargo. The ATLS system usually consists of two parts: the system on the truck (or other industrial vehicle) and the system on the platform. The Automatic Truck Loading System (ATLS) can significantly save loading and unloading time and manpower, thereby shortening the waiting and detention time of transportation vehicles in logistics centers. The most significant advantage of the ATLS system is that it can load pallets onto containers without manual intervention, allowing operators to achieve maximum efficiency through precise workflow and stable operating speed. When the truck arrives at the platform, follow the truck guidance device installed on the platform to reach the designated position; Connect the system on the truck with the system on the platform through the visual system, and then lock the truck; The driver activates the automatic loading and unloading system, and the goods are automatically transported from the truck to the platform or from the platform to the truck in one go. The entire vehicle can be loaded and unloaded in at least 2 minutes. By adding conveyors, lifting platforms, turntables, and elevators connected to the automatic loading and unloading system, the automatic loading and unloading system and the automatic warehousing system can seamlessly interface, thereby achieving fully automated operations from the inside of the warehouse to the loading and transportation of goods out of the warehouse

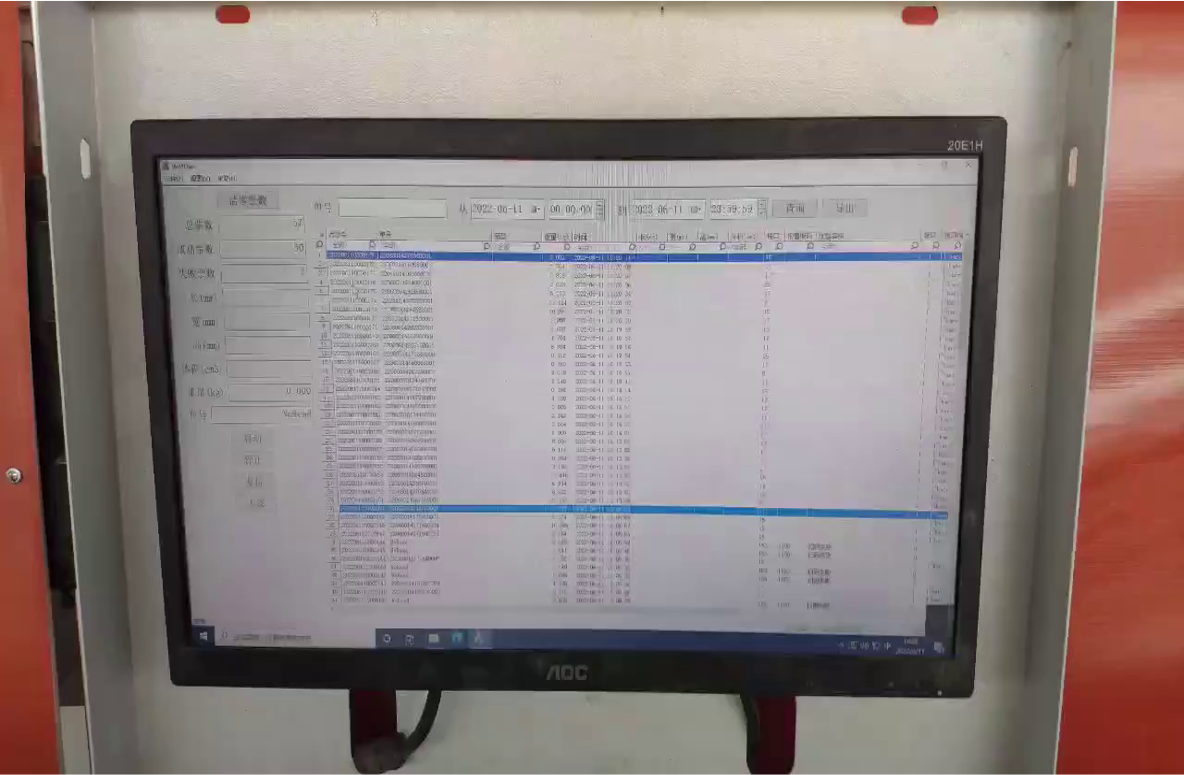

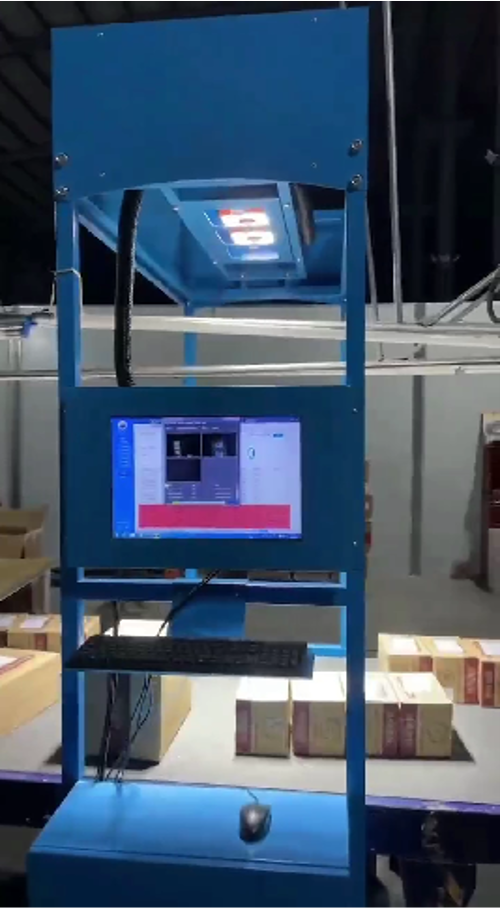

Conveyor belt machine case

Our company’s belt line integrated projects includes circular cross belt sorter and telescopic belt conveyor machine. The company has independent intellectual property rights, through years of practices, product’s quality takes lead in the field. Currently has finished 400 projects share by STO, Yuantong, J&T, Baishi and Products include small circular cross belt sorting machine, belt conveyor, telescopic belt conveyor. We have won many medals such as "Quality Supplier" and "Strategic Supplier" issued by customers, and the company has honorary titles such as "High-tech Enterprise", "Private Technology Enterprise" and "Advanced Private Enterprise" issued by the local government.

1. Unique design of belt anti-deviation

2. The functions of conveying, ascending and descending can be realized

3. Conveying speed: 0-120m/min

4. Spray plastic treatment on the surface of fuselage and outrigger

5. The assembly test design is convenient to install, easy to adjust and stable in performance

6. The size can be customized according to customer requirements

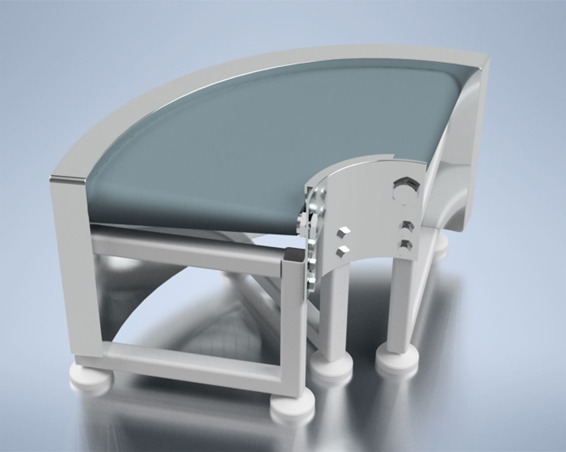

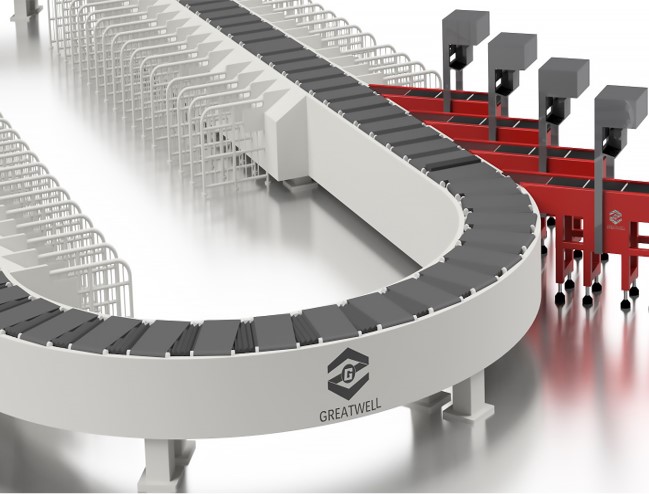

Cross belt sorter

The Cross belt sorter is an extremely complex system integrated product, composed of many kinds of mature equipments, customized structural equipments, network cable, cables, and independent R&D of information technology. This system is modular control of each independent function,and send executive commands also collect execution of each module to take control.

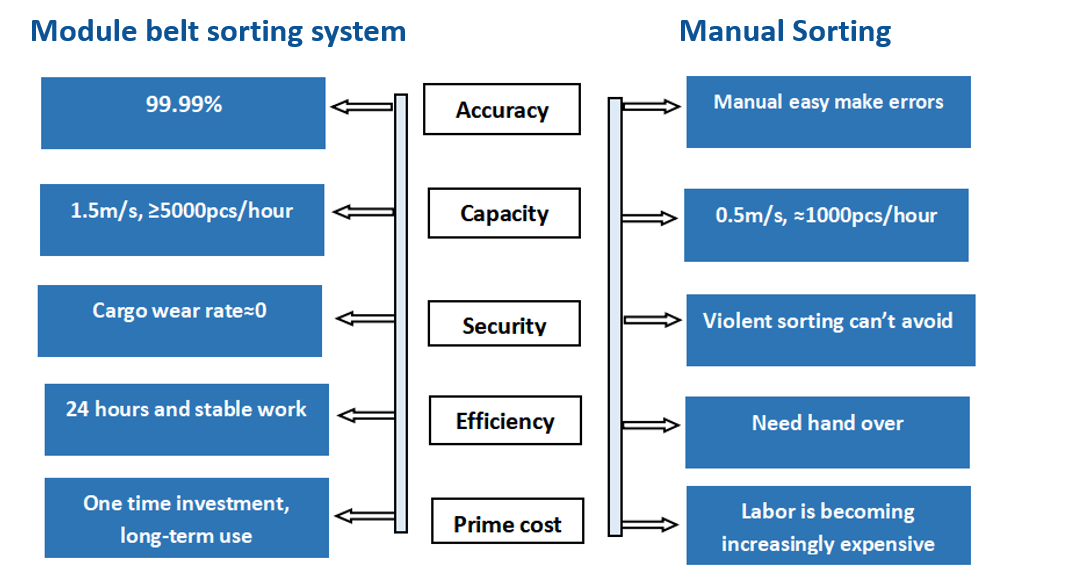

Roller center conveyor line for warehouse

Roller centering machines are often used in transportation equipment such as warehousing and logistics,After the package is inducted from anywhere, it can be put into the center through this roller conveyor.Centering machine is usually connected with automatic single piece separation equipment, belt conveyor, sorting equipment, turning conveyor, etc.The machine easy installation, low cost and firm structure.It can carry 60Kg/㎡, and the size of sorted goods is generally between 100 * 100 and 1000 * 800mm, with a wide range of applications.Use scenarios include pretreatment before logistics sorting (generally at the back end of the separation equipment); Confluence of two conveying lines; Divert to another conveyor line; Placed in the front section of the edger, etc

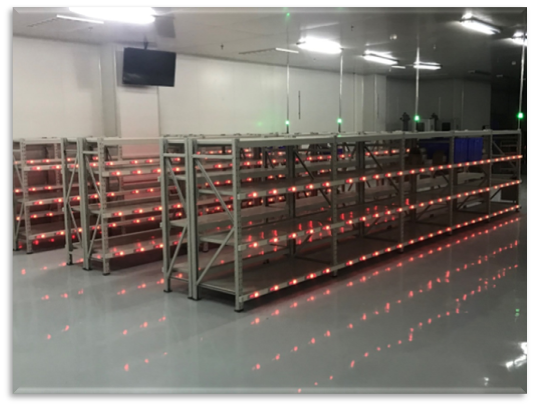

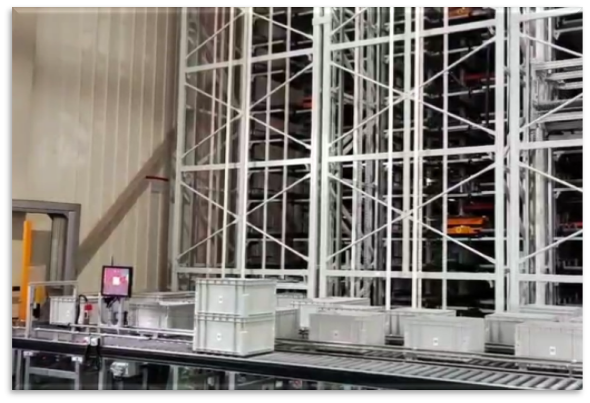

Track type RGV robot - Intelligent 3D automatic warehouse

Multi layer shuttle car adopts intensive storage instead of attic storage, which greatly reduces the storage land area. The automatic system of multi-layer shuttle car is adopted to realize unmanned operation in the storage area. In the project, laneways, robots and floor changing elevators are used to realize the storage, storage and floor changing of multi-layer robots through system scheduling. The principle of centralized box grouping, centralized shelving and instant picking is adopted for material operation. The form of automatic transmission is adopted in the storage and picking room to truly realize the mode of picking goods to people. The whole information process is truly connected, from SAP to the barcode system to the WMS and WCS of the multi-layer shuttle system, realizing seamless data connection, so as to realize the information management of all materials in the warehouse area, warehouse location, bin, pallet and carton. Sorting and storage adopt system scheduling and ergonomic design to reduce the working pressure of people and reduce the error rate of manual errors. Real time tracking of all goods and full process monitoring of all equipment operation status.

Stacker - Intelligent 3D automatic warehouse

Stackers can be divided into light, heavy and mini loads according to the load capacity, high and low stackers according to the loading height, and single depth and double depth stackers according to the loading depth.The rail roadway stacker is mainly composed of the machine body (including column, upper beam and lower beam), cargo platform, horizontal running mechanism, lifting mechanism, fork mechanism and electrical control device.The stacker is controlled by PLC and driven by frequency conversion speed regulation. Communication between the stacker and ground equipment through infrared optical communication.Each PLC and the monitoring computer form a network through bus connection.There is an operation interface on the stacker. The stacker can be operated locally or online by the upper computer.The monitoring computer and the management computer are connected via TCP/IP protocol, and the PLC and the inverter are connected via profibus.